About the project

Acronym: New Environmental friendly and Durable conCrete, integrating industrial by-products and hybrid systems, for civil, industrial and offshore applications – EnDurCrete

Overall Concept

Ordinary Portland cement has been considered for many years the benchmark structural material for durable buildings and infrastructures, as well as for marine environments. However, its production process consumes significant mineral resources (good-quality limestone and clay), energy and fuel, and creates greenhouse gas emissions. Various efforts are underway to improve the environmental friendliness of concrete, by integrating supplementary cementitious materials (SCM), such as by-products of industrial processes. Nevertheless, current state of the art sustainable solutions based on high substitution rate of Portland cement clinker by SCM occasionally lead to limited performance and durability of concrete structures, particularly critical when applied in harsh conditions. All these aspects affect also the resource consumption, waste production, environmental and economic costs of repair and replacement.

In this framework, EnDurCrete Project aims to develop a new cost-effective sustainable reinforced concrete for long lasting and added value applications. The concept is based on the integration of novel low-clinker cement including high value industrial by-products, new nano and micro technologies and hybrid systems ensuring enhanced durability of sustainable concrete structures with high mechanical properties, self-healing and self-monitoring capacities.

EnDurCrete concept is based on the following novel technologies and tools

→ Novel cement, by including sustainable, high-quality supplementary cementitious materials (classified coal combustion fly ashes and ground granulated blast furnace slag).

→ New multifunctional coatings enabling concrete self-healing properties based on resin microencapsulation and protecting both concrete and rebar from aggressive agents.

→ New smart fillers based on nano-modified clays, for anti-corrosion properties and based on micro carbon-based materials (such as carbonaceous inerts like char and the finer fraction of a used foundry sand, derived from industrial by-products) for mechanical and self-sensing properties. The structural self-sensing properties will be complemented with environmental sensors casted in concrete.

→ Concrete non-metallic multifunctional reinforcing systems, based on technical textiles integrated with optical-fibre sensors, enabling both structural reinforcement and continuous structural health monitoring. The systems will be optimised aiming at a proper trade-off between productivity, robustness, and concrete reinforcement adhesion.

→ Advanced non-destructive continuous monitoring and testing tools and procedures, including technologies tuned for the self-sensing concrete systems. Durability properties of the components will be assessed and monitored. The new developed tools will be integrated by conventional durability testing procedures.

→ Coupled experimental and computational approach for theoretical and experimental understanding of factors affecting durability. Modelling and simulations applied at micro-mesoscale are carried out defining representative elementary volumes of cement paste, mortar, and concrete as well as modelling applied at macroscale is performed representing the whole concrete infrastructures. These continuum models are solved by finite elements analysis. The combined experimental and computational approach will enable long-term durability assessment and resulting service life prediction of the target infrastructures exposed to severe environment.

Overall concept at a glance

Demonstration and Prototyping

All the technologies developed during the EnDurCrete project will be tested at demonstration level:

Maritime port in Spain

Puerto de Musel, in Gijón - North of Spain, located in a small wharf in the North of the port where ACCIONA is currently carrying out research works, EnDurCrete specimens will be hold by metallic structures.

Puerto de Musel, in Gijón - North of Spain, located in a small wharf in the North of the port where ACCIONA is currently carrying out research works, EnDurCrete specimens will be hold by metallic structures.

The exposure classes to be considered are XS1, XS2, and XS3. Multiple testing zones are going to be adopted:

- Aerial: specimens not in contact with water;

- Tidal: specimens subjected to tidal cycles;

- Submerged: specimens totally under water.

Monitoring:

- Electrical impedance on the 4 panels dedicated to self-sensing; 2 panels will be placed in the aerial zone, the other two in the tidal one.

- Environmental data (temperature, RH, etc.) will be monitored capturing data from the closest weather station.

Inspection:

- Non‐Destructive Testing: Computer Vision (CV) and thermography (system mounted on a drone) on a pre-cracked panel placed in the aerial zone.

- Surface Resistivity Testing: electrical resistivity of concrete panels with a 4‐point probe system (Resipod proceq, compliant to AASHTO T 358) at specimen installation and after 12 months of exposure.

- Destructive Testing:

- Compressive strength

- Porosity

- Sulphates attack and related micro‐level analyses with SEM/EDAX

- Carbonation testing

- Freeze‐thaw

- Chloride diffusion test

- Water penetration test to derive water permeability

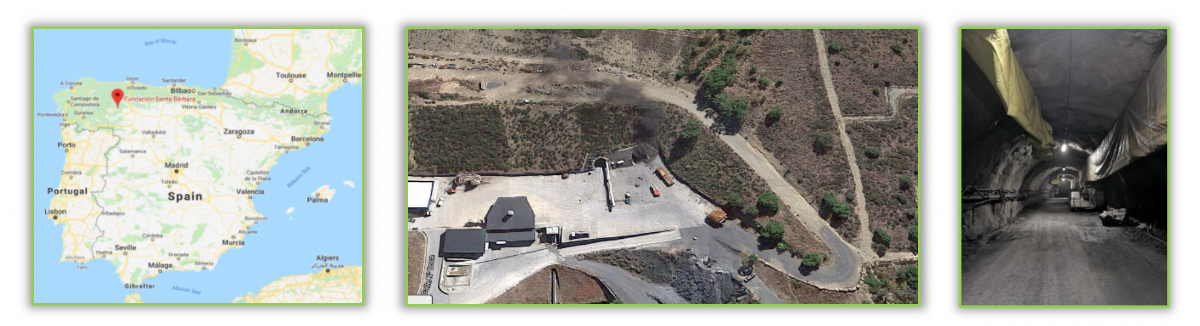

Tunnel in Spain

Demonstrator located at Fundación Santa Bárbara, La Ribera del Folgoso, Leon - North of Spain, 7 panels (2 of them 4 meters long) will be installed.

Monitoring:

- Self‐diagnosis property will be assessed by optical fibers

- Environmental sensors: commercial environmental sensors (T and RH)

- Electrical impedance on the 4 panels dedicated to self-sensing

Inspections:

- Non‐Destructive Testing: CV and thermography on a pre‐cracked concrete panel

- Destructive Testing:

- Compressive

- Porosity

- Freeze‐thaw

- Water penetration test to derive water permeability

Offshore structure in Norway (Stord, Norway)

The exposure classes of offshore demo site are XS3 and XF4. Three different testing zones for specimens are being set‐up:

- Above splash zone: specimens not in contact with water;

- Splash: specimens subjected to splashes of water;

- Submerged: specimens totally under water.

Monitoring:

- Durability of self‐diagnosis property will be assessed by means of checking the optical fibers behavior over time

- Corrosion sensors

- Environmental sensors

As for periodic testing on small specimens, the following tests are going to be performed

- Destructive tests:

- Compressive strength

- Porosity

- Freeze‐thaw

- Chloride penetration test to derive chloride content

Bridge in Croatia

Krk Bridge, Croatia, North Adriatic Sea in Croatia, the bridge has been built between 1976 and 1980, and since then it has gone under numerous maintenance and remediation measures, due to the corrosion problems. Due to the very aggressive marine environment, it is suffering from durability corrosion problems mostly caused by corrosion of reinforcement.

Krk Bridge, Croatia, North Adriatic Sea in Croatia, the bridge has been built between 1976 and 1980, and since then it has gone under numerous maintenance and remediation measures, due to the corrosion problems. Due to the very aggressive marine environment, it is suffering from durability corrosion problems mostly caused by corrosion of reinforcement.

The exposure classes of the bridge demo site are XS1, XS2, and XS3. There are multiple testing zones for specimens:

- Splash: specimens subjected to splashes of water;

- Tidal: specimens subjected to tidal cycles;

- In‐water: specimens totally submerged.

Monitoring:

Corrosion/environmental sensors

Testing:

Destructive testing: compressive strength